+86 022 2376 3704

+86 022 2376 3704

Feb. 26, 2025

In infrastructure construction, steel strands are key materials, and their corrosion resistance is directly related to the service life and safety of the project.

After professional anti-corrosion treatment, steel strands can resist the erosion of the surrounding medium, making them less likely to rust in harsh environmental conditions such as humidity and saline-alkali land, thus extending their service life and reducing maintenance costs. Improving the corrosion resistance of steel strands is essential for many industrial and construction applications.

The following are some common methods to enhance the corrosion resistance of steel strands:

Ⅰ, Internal factors:

Optimize material selection. By improving the selection and mixing of materials, the corrosion resistance of steel strands can be improved. For example, stainless steel strands are used to improve corrosion resistance from the material's essence. By adding alloy elements such as chromium and nickel during the steel smelting process, the organization structure of the steel strands is changed from the inside, so that they have good corrosion resistance. This corrosion resistance is determined by the alloy composition and microstructure inside the steel strands. It does not depend on additional external protective coatings or treatments, but mainly depends on the internal factors of the material itself.

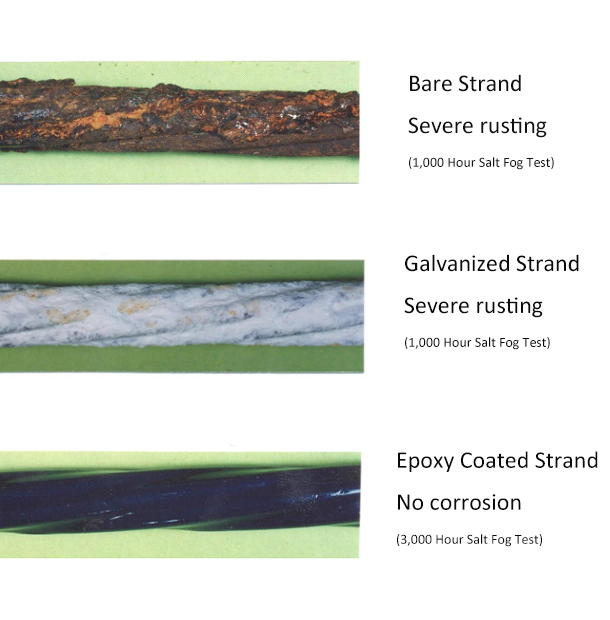

For example, in the salt spray corrosion test, ordinary carbon steel strands are severely corroded after 1000 hours, while stainless steel strands with 18% chromium and 8% nickel content have only slight discoloration on the surface after 3000 hours of salt spray test, and there are almost no rust spots. The chromium element forms a dense chromium oxide passivation film on the surface of the steel strand. This film is tightly attached to the steel surface, effectively preventing oxygen and moisture from chemically reacting with the internal metal. Even if the passivation film is partially damaged, the surrounding chromium elements can be quickly oxidized and repaired to maintain good corrosion resistance. The nickel element enhances the stability of the steel and further improves its corrosion resistance, especially when it comes to resisting chloride ion corrosion.

(3,000 Hour Salt Fog Test)

Ⅱ, External factors:

Filled epoxy coated steel strands are based on traditional steel strands, with special corrosion-resistant materials filled in the gaps and epoxy coating applied on the surface to achieve corrosion protection. These externally added substances form a physical barrier that isolates the external corrosive medium, thereby protecting the inside of the steel strand from erosion. Its anti-corrosion effect mainly depends on external factors such as the coating and filling materials applied to the outside of the steel strand.

Experimental data show that after 1,000 hours of salt spray testing, ordinary steel strands are severely corroded, while the filled epoxy coated steel strands have a complete coating and basically no signs of rust in the 3,000-hour experimental period. This is due to the shielding effect of the epoxy coating, which can effectively prevent external corrosive media such as chloride ions, oxygen and moisture from contacting the steel strand matrix; the filling material further prevents the medium from invading from the internal gaps of the steel strand, forming a double protection mechanism.

When the coating is slightly scratched, the filling material can inhibit the spread of corrosion along the gap, greatly extending the corrosion resistance life of the steel strand. There is, in addition, one further point to make that the epoxy coated steel strand is capable of enduring over 100 years when used as an external cable in a concrete box girder. If you want to know more details, please contact us.

(The experimental results are for reference only, please refer to the actual situation.)

Ⅲ, Reasonable storage:

When storing steel strands, choose a well-ventilated warehouse and reduce the humidity of the environment. Use and store the steel strands in a dry environment to avoid direct contact with soil and moisture to reduce the chance of corrosion. For example, when storing steel strands in a warehouse, you can use dehumidification equipment to reduce air humidity and maintain a dry and ventilated state.

Ⅳ, Regular inspection and maintenance:

The steel strands should be inspected before use to ensure that they are free of rust. During use, pay attention to keeping the steel strands clean and remove stains such as oil in time to prevent corrosion of the steel strands.

In short, filled epoxy coated steel strands are relatively low-cost and suitable for large-scale infrastructure construction in ordinary environments, such as general bridges and roads; but once the coating is severely damaged, the protective effect will be greatly reduced. Stainless steel strands are highly corrosion-resistant and require almost no additional maintenance. They are suitable for environments with high corrosion risks, such as offshore platforms and coastal buildings.

In actual projects, the type of steel strand can be reasonably selected according to different environmental and cost requirements, or composite protection measures can be adopted, such as applying a light coating on the surface of the stainless steel strand to further improve its corrosion resistance in extreme environments, ensuring that the steel strand will not rust under various working conditions, and ensuring the long-term safety and reliability of the project.

Whether you'd like to get more info on what, need help with what you're creating anytime… anywhere.

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

Quick Links

Product Category

Subscribe Newsletter

Welcome to subscribe toour email message!