+86 022 2376 3704

+86 022 2376 3704

Prestressed Material

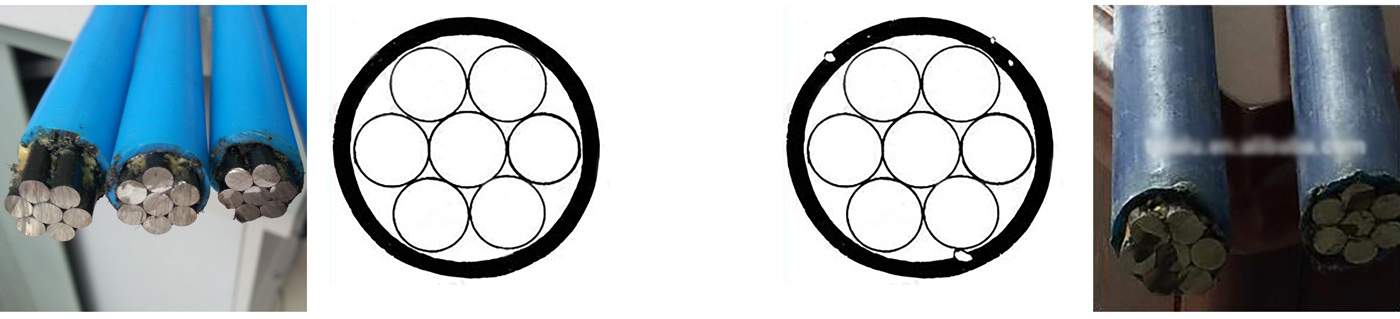

Unbonded Steel Strand for Prestressed Concrete

This product is suitable for cast-in-place concrete projects. Such as cast-in-place slabs, geotechnical projects, foudation piles, slope support,etc.

It has the characteristics of no need to reserve holes, easy construction, saving bellows materials, and random bending.

Its application in recoverable anchor cables saves a lot of cost for engineering projects.

The specifications is conforming with JG 161-2004.

Steel is in accordance with GB/T5224-2014, or EN10138/BS5896,or ASTM A416, or other standards clients require.

Sheathing: GB 11116,GB/T9341. Grease: JG3007-1993.

ADVANTAGES

Advantages:

Its application in recoverable anchor cables saves a lot of cost for engineering projects.

The specifications is conforming with JG 161-2004.

Steel is in accordance with GB/T5224-2014, or EN10138/BS5896,or ASTM A416, or other standards clients require.

Sheathing: GB 11116,GB/T9341. Grease: JG3007-1993.

USE

Use:

Its application in recoverable anchor cables saves a lot of cost for engineering projects.

SPECIFICATIONS

YXXK-UPS Series Unbonded PC Strand (Ref. JG161-2004, Single layer HDPE Sheathing)

| CODE | Steel | Grease | Sheathing thickness | μ | κ | ||

| W3 (g/m) | (mm) | ||||||

| Diameter (mm) | Section Area (mm2) | Tensile Strength (Mpa) | (no less than) | (no less than) | |||

| YXXK-UPS9 | 9. 53 | 54. 84 | 1860 | 32 | 0. 8 | 0.04~ 0.1 | 0.003 ~ 0.004 |

| YXXK-UPS13 | 12. 7 | 98. 71 | 1860 | 43 | 1 | 0.04 ~ 0.1 | 0.003 ~ 0.004 |

| YXXK-UPS13 | 12. 9 | 100 | 1860 | 45 | 1 | 0.04 ~ 0.1 | 0.003 ~ 0.004 |

| YXXK-UPS15 | 15. 24 | 140 | 1860 | 50 | 1 | 0.04 ~ 0.1 | 0.003 ~ 0.004 |

| YXXK-UPS15 | 15. 7 | 150 | 1860 | 53 | 1 | 0.04 ~ 0.1 | 0.003 ~ 0.004 |

μ- Friction coefficient between steel strands and inner wall of sheath in unbonded prestressing tendon

κ - Friction coefficient considering local deviation per meter length of unbonded prestressing tendon

Why should I buy this unbonded prestressed steel strand?

Steel Part:

- high tensile strength steel strand is conforming with international standard, the T/S grade is more than 1920 Mpa

- Straightness is excellent, bow height per meter is less than 2mm

- the steel is newly produced, rust steel and old steel is forbidden.

- dust,granular objects, corrosive substances, oil, on the surface of steel is not allowed.

Grease Part:

- The anti-corrosion grease used in the production of unbonded prestressed steel strands has good chemical stability and have no corrosive effect on surrounding materials; it can block water, moisture and corrosion, good lubricating performance, reduce friction resistance, does not flow at high temperature and not brittle at low temperature within the specified temperature range.

| Test Item | Test Ways | Requirement | |

| Work cone penetration | 25℃, 0.1mm | GB/T269 | 265-295 |

| Corrosion | 45# steel, 100℃,24hours | SH/T0331 | - |

| Drop point | ℃, no less than | GB/T4929 | 160 |

| Moisture | %,no more than | GB/T512 | 0.1 |

| Stencil oil | %,(100℃,24hours),no more than | SH/T0324 | 8 |

| Evaporation losses | %,(99℃,24hours),no more than | GB/T7325 | 2 |

| Low temperature performance | -40℃,30 minuts | SH0387 | - |

| Humid heat test | grade,(45#steel30D),no more than | GB/T2361 | 2 |

| Sailt spray analysis | grade,(45#steel30D),no more than | SH/T0081 | 2 |

| Oxidation Stability | 99℃,100hours,785kpa, pressure no more than | SH/T0325 | 147 |

| Oxidation Stability | acide value after oxidation mgKOH/g, no more than | GB/T264 | 1 |

| PH Value | - | PH test paper | 7. 0-8. 0 |

| Compatibility casing oil absorption | %,(65℃,40D),no more than | HG2-146 | 10 |

| Tensile strength change rate to casing compatibility | %,(65℃,40D),no more than | GB1040 | 30 |

HDPE Part:

| Properties | Test Ways | Requirements |

| Large and small grains, g/kg | SH/T 1541.1-2019 | ≤5 |

| Black grain, piece/kg | SH/T 1541.1-2019 | 0 |

| Color grains, piece/kg | SH/T 1541.1-2019 | ≤5 |

| Snake skin grains, piece/kg | SH/T 1541.1-2019 | ≤10 |

| Density (23℃), g/cm3 | GB/T1033.2 or ASTM D1505 | 0.9510+-0.0020 |

| Enviromental Stress Crack Resistance | Condition A, F50,100% lgepal CO-630,ASTM D1693 | ≥30 hours |

| Condition B, F50:35; Bottles ESCR:250, 60℃, F50 | ||

| Melt Flow | Condition 190/2.16,ASTM D1238 | ≤0.35 g/10min |

| GB/T 3682. 1 | 1.0+-0.2 | |

| Tensile Strength | 2 in per min, ASTM D638 Type IV | ≥28MPA |

| Elongation at break | 2 in per min, ASTM D638 Type IV | ≥600% |

| Flexural Modulus | ASTM D790 | 1. 378Gpa |

| Brittleness Temperature | ASTM D746 | Max -118℃ |

What makes this product different to other factory's unbonded prestressed steel strand?

Ours Appearance is very good.

Thickness uniform, surface smooth.

Friction coefficient between steel strands and inner wall of sheath in unbonded prestressing tendon is very excellent.

Friction coefficient considering local deviation per meter length of unbonded prestressing tendon is very small.

Other factory's product

Granulated impurity in the coating, surface is not smooth, leak grease, μ and κ is not good.

Whether you'd like to get more info on what, need help with what you're creating anytime… anywhere.

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

Quick Links

Product Category

Subscribe Newsletter

Welcome to subscribe toour email message!