+86 022 2376 3704

+86 022 2376 3704

Precision rolled threaded steel

Threaded steel bars for prestressed concrete (also called precision rolled threaded steel) are large-diameter, high-strength, high-dimensional precision straight bars with discontinuous external threads rolled on the entire steel bar. The steel bar can be connected with a connector with an internal thread or anchored with a threaded nut at any cross section.

Finish-rolled threaded nut, also known as finished rolled threaded steel nut, is a high-strength Finish-rolled threaded nut. When in use, the force of the finish-rolled threaded nut is applied by applying pre-tension inside it, and then generating friction resistance on the contact surface between the connected parts to bear the external load. It is usually used in conjunction with a finished rolled threaded steel plate.

The finish-rolled threaded coupler refers to the precision-rolled threaded steel connector, which is a precision-rolled threaded steel anchor that can directly connect two steel bars together. It is an anchoring device used in prestressed concrete. It is an anchoring tool used in post-tensioned structures or components to maintain the tension of the prestressed tendons and transfer it to the inside of the concrete. It is also called a prestressed anchor.

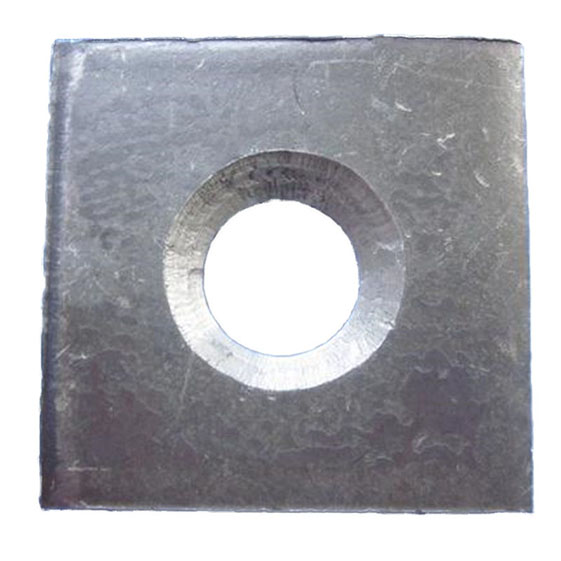

Finished-rolled threaded backing plate, also known as finished rolled threaded steel plate, are an important part of the finished rolled threaded steel accessories anchor. They are used together with finished rolled nuts and are the most used part in the project. Finished-rolled threaded backing plate are divided into flat plate, conical plate and spherical plate. Flat plate are often used for fixed ends, and conical plate are often used for tensioning ends. The size of finished-rolled threaded backing plate can also be processed according to the requirements of relevant construction.

(Precision rolled threaded steel, Finish-rolled threaded nut, Finish-rolled threaded coupler, Finished-rolled threaded backing plate)

ADVANTAGES

Characteristics of precision rolled threaded steel:

High strength: high yield strength and tensile strength, stable and reliable quality. Common strength grades include PSB785, PSB830, PSB930, PSB1080, etc., which can meet the needs of different large-scale projects.

High precision: high dimensional accuracy, uniform thread specifications, regular tooth shape, ensuring the reliability and construction accuracy of connection with anchors.

Good machinability: good cold bending and welding performance, convenient for cutting, bending and connection at the construction site. Save steel bars, reduce component area and weight.

Strong adaptability of connection method: simple connection and anchoring, strong adhesion, safe and reliable tension anchoring, and convenient construction.

High corrosion resistance: generally surface anti-corrosion treatment is carried out, such as galvanizing, plastic coating, etc., which can effectively resist external environmental erosion and extend service life.

USE

Application fields of finished rolled threaded steel bars:

Due to its high strength, high precision and fatigue resistance, the precision rolled rebar has a wide range of applications, mainly in the following key projects:

1. Prestressed concrete system

Bridge engineering: cable anchorage ends of cable-stayed bridges, suspenders of suspension bridges, and external prestressed tendons of continuous beam bridges.

Rail transit facilities: longitudinal tensioning tendons of high-speed rail sleepers, and connecting bolts of subway segments.

Large buildings: prestressed anchors of stadium domes and large-span beams of exhibition centers.

2. Heavy machinery and equipment systems

Engineering machinery: force transmission rods of shield machine propulsion systems, pressure bearing screws of hydraulic jacks.

Energy equipment: wind power tower anchor bolts, turbine main shaft fasteners.

Industrial equipment: heavy stamping machine base anchor bolts, port crane track fixings.

3. Special structure anchoring system

Nuclear power plant: containment prestressed steel bundles, reactor pressure vessel anchor rods.

Hydropower station/dam: gate hoist anchor bolts, high-strength tie rods for dam reinforcement.

Geological disaster protection: mountain slope anchor cables, prestressed anchor rods for tunnel support.

4. Transportation infrastructure system

Highway: sound barrier column foundation anchor rod, overpass expansion joint anchor.

Railway system: contact network pillar anchor bolt, track plate fine adjustment screw.

Cross-sea project: immersed tube tunnel pipe segment connection bolt, submarine pile foundation reinforcement tie rod.

5. Extreme environment engineering system

Corrosion-resistant scenario: coastal chemical facilities (epoxy resin coated fine rolled rebar), saline-alkali land bridge.

Low temperature environment: oil and gas pipeline support anchor bolts in high-cold areas (-50℃ low temperature toughness material).

Fatigue-resistant scenario: airport runway joint anchor (withstands high-frequency vibration of aircraft takeoff and landing).

SPECIFICATIONS

Product Parameters of precision rolled threaded steel | |||

Nominal Diameter / mm | Level | Nominal cross-sectional area / mm2 | Theoretical weight kg/m |

Φ15 | PSB830 | 177 | 1.4 |

Φ20 | PSB500 | 314 | 2.47 |

Φ25 | PSB500 / 830 / 930 / 1080 | 491 | 4.1 |

Φ32 | PSB830 / 930 / 1080 | 804 | 6.65 |

Φ36 | PSB830 / 930 / 1080 | 1080 | 8.41 |

Φ40 | PSB830 / 930 / 1080 | 1257 | 10.34 |

Φ50 | PSB830 / 930 / 1080 | 1963 | 16.28 |

Mechanical Properties:

Mechanical Properties | ||||||||||||||

Diameter / mm | Cross-sectional area / mm | Weight Kg/m | PSB830 | PSB930 | PSB1080 | |||||||||

Min Yield Stress/Load | Min Ultimate Stress/Load | Min Yield Stress/Load | Min Ultimate Stress/Load | Min Yield Stress/Load | Min Ultimate Stress/Load | |||||||||

Mpa | KN | Mpa | KN | Mpa | KN | Mpa | KN | Mpa | KN | Mpa | KN | |||

15 | 177 | 1.4 | 830 | 147 | 1030 | 182 | 930 | 165 | 1080 | 191 | 1080 | 191 | 1230 | 218 |

20 | 314 | 2.47 | 830 | 261 | 1030 | 323 | 930 | 292 | 1080 | 339 | 1080 | 339 | 1230 | 386 |

25 | 491 | 4.1 | 830 | 408 | 1030 | 506 | 930 | 457 | 1080 | 530 | 1080 | 530 | 1230 | 604 |

32 | 804 | 6.65 | 830 | 667 | 1030 | 828 | 930 | 748 | 1080 | 868 | 1080 | 868 | 1230 | 989 |

36 | 1018 | 8.41 | 830 | 845 | 1030 | 1049 | 930 | 947 | 1080 | 1099 | 1080 | 1099 | 1230 | 1252 |

40 | 1257 | 10.34 | 830 | 1043 | 1030 | 1295 | 930 | 1169 | 1080 | 1358 | 1080 | 1358 | 1230 | 1546 |

50 | 1963 | 16.28 | 830 | 1629 | 1030 | 2022 | 930 | 1826 | 1080 | 2120 | 1080 | 2120 | 1230 | 2414 |

Elongation at fracture A / % | ≥7 | ≥7 | ≥6 | |||||||||||

Total Elongation at max force Agt / % | ≥3.5 | |||||||||||||

Relaxation at 1000h | ≤4 | |||||||||||||

Modulus of elasticity / Mpa | 2 x 105 | |||||||||||||

PACKAGE

We support customerization package.

RELATED PRODUCTS

Whether you'd like to get more info on what, need help with what you're creating anytime… anywhere.

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

Quick Links

Product Category

Subscribe Newsletter

Welcome to subscribe toour email message!