+86 022 2376 3704

+86 022 2376 3704

Precision rolled threaded steel

Reinforcing Bar are further rolled by a high-precision rolling mill on the basis of hot-rolled ribbed steel bars. They have fine-rolled threads on their surface and can be closely matched with anchors, connectors, etc. They are mainly used for prestressed construction of large concrete structures. Prestress is applied by tensioning, and the elastic retraction of the steel bars is used to generate pre-compressive stress on the concrete, thereby improving the crack resistance, durability and bearing capacity of the concrete structure.

ADVANTAGES

High strength: high yield strength and tensile strength, stable and reliable quality. Common strength grades include PSB785, PSB830, PSB930, PSB1080, etc., which can meet the needs of different large-scale projects.

High precision: high dimensional accuracy, uniform thread specifications, regular tooth shape, ensuring the reliability and construction accuracy of connection with anchors.

Good machinability: good cold bending and welding performance, convenient for cutting, bending and connection at the construction site. Save steel bars, reduce component area and weight.

Strong adaptability of connection method: simple connection and anchoring, strong adhesion, safe and reliable tension anchoring, and convenient construction.

High corrosion resistance: generally surface anti-corrosion treatment is carried out, such as galvanizing, plastic coating, etc., which can effectively resist external environmental erosion and extend service life.

USE

Application areas:

Highway bridges, railway bridges, urban interchanges, urban light rail, high-rise buildings, water conservancy and hydropower dams, port terminals, rock slope anchoring, foundation reinforcement, tunnel mine top anchoring, etc.

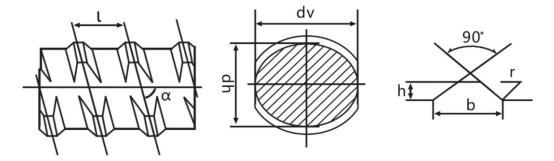

SPECIFICATIONS

Diameter /mm | dh/mm | dv/mm | h/mm | b/mm | l/mm | r/mm | α | |||||

Size | Tolerance | Size | Tolerance | Size | Tolerance | Size | Tolerance | Size | Tolerance | |||

15 | 14.7 | ±0.2 | 14.4 | ±0.5 | 1.0 | ±0.2 | 4.2 | ±0.3 | 10.0 | ±0.2 | 0.5 | 78.5º |

20 | 20.0 | ±0.4 | 20.0 | +0.4-0.8 | 1.3 | ±0.3 | 4.8 | ±0.5 | 10.0 | 1.2 | 80.5º | |

25 | 25.0 | 25.0 | 1.6 | 6.0 | 12.0 | 1.5 | 81º | |||||

32 | 32.0 | ±0.5 | 32.0 | +0.5-1.2 | 2.0 | ±0.4 | 7.0 | 16.0 | 2.0 | 81.5º | ||

36 | 36.0 | 36.0 | 2.2 | ±0.4 | 8.0 | 18.0 | ±0.3 | 2.5 | 81.5º | |||

40 | 40.0 | 40.0 | 2.5 | ±0.5 | 8.0 | 20.0 | 2.5 | 81.5º | ||||

50 | 50.0 | 50.0 | 3.0 | -0.5 | 9.0 | 24.0 | 2.5 | 81.8º | ||||

Mechanical Properties:

Mechanical Properties | ||||||||||||||

Diameter / mm | Cross-sectional area / mm | Weight Kg/m | PSB830 | PSB930 | PSB1080 | |||||||||

Min Yield Stress/Load | Min Ultimate Stress/Load | Min Yield Stress/Load | Min Ultimate Stress/Load | Min Yield Stress/Load | Min Ultimate Stress/Load | |||||||||

Mpa | KN | Mpa | KN | Mpa | KN | Mpa | KN | Mpa | KN | Mpa | KN | |||

15 | 177 | 1.4 | 830 | 147 | 1030 | 182 | 930 | 165 | 1080 | 191 | 1080 | 191 | 1230 | 218 |

20 | 314 | 2.47 | 830 | 261 | 1030 | 323 | 930 | 292 | 1080 | 339 | 1080 | 339 | 1230 | 386 |

25 | 491 | 4.1 | 830 | 408 | 1030 | 506 | 930 | 457 | 1080 | 530 | 1080 | 530 | 1230 | 604 |

32 | 804 | 6.65 | 830 | 667 | 1030 | 828 | 930 | 748 | 1080 | 868 | 1080 | 868 | 1230 | 989 |

36 | 1018 | 8.41 | 830 | 845 | 1030 | 1049 | 930 | 947 | 1080 | 1099 | 1080 | 1099 | 1230 | 1252 |

40 | 1257 | 10.34 | 830 | 1043 | 1030 | 1295 | 930 | 1169 | 1080 | 1358 | 1080 | 1358 | 1230 | 1546 |

50 | 1963 | 16.28 | 830 | 1629 | 1030 | 2022 | 930 | 1826 | 1080 | 2120 | 1080 | 2120 | 1230 | 2414 |

Elongation at fracture A / % | ≥7 | ≥7 | ≥6 | |||||||||||

Total Elongation at max force Agt / % | ≥3.5 | |||||||||||||

Relaxation at 1000h | ≤4 | |||||||||||||

Modulus of elasticity / Mpa | 2 x 105 | |||||||||||||

PACKAGE

we support customized packaging ways.

Whether you'd like to get more info on what, need help with what you're creating anytime… anywhere.

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

Quick Links

Product Category

Subscribe Newsletter

Welcome to subscribe toour email message!