+86 022 2376 3704

+86 022 2376 3704

Precision rolled threaded steel

Threaded steel bars for prestressed concrete (also called precision rolled threaded steel) are large-diameter, high-strength, high-dimensional precision straight bars with discontinuous external threads rolled on the entire steel bar. The steel bar can be connected with a connector with an internal thread or anchored with a threaded nut at any cross section.

Brief introduction:

Precision rolled threaded steel are further rolled by a high-precision rolling mill on the basis of hot-rolled ribbed steel bars. They have fine-rolled threads on their surface and can be closely matched with anchors, connectors, etc. They are mainly used for prestressed construction of large concrete structures. Prestress is applied by tensioning, and the elastic retraction of the steel bars is used to generate pre-compressive stress on the concrete, thereby improving the crack resistance, durability and bearing capacity of the concrete structure.

ADVANTAGES

Characteristics of precision rolled threaded steel:

High strength: high yield strength and tensile strength, stable and reliable quality. Common strength grades include PSB785, PSB830, PSB930, PSB1080, etc., which can meet the needs of different large-scale projects.

High precision: high dimensional accuracy, uniform thread specifications, regular tooth shape, ensuring the reliability and construction accuracy of connection with anchors.

Good machinability: good cold bending and welding performance, convenient for cutting, bending and connection at the construction site. Save steel bars, reduce component area and weight.

Strong adaptability of connection method: simple connection and anchoring, strong adhesion, safe and reliable tension anchoring, and convenient construction.

High corrosion resistance: generally surface anti-corrosion treatment is carried out, such as galvanizing, plastic coating, etc., which can effectively resist external environmental erosion and extend service life.

USE

Specifications of precision rolled threaded steel:

Prestressed concrete rebar is divided into grades according to yield strength, and its code is "PSB" plus the specified minimum yield strength. P, S, and B are the first letters of Prestressing, Screw, and Bars, respectively. For example: PSB830 represents a steel bar with a minimum yield strength of 830 MPa.

PSB500, PSB785, PSB830, PSB930, PSB1200, PSB1080/15mm, 20mm, 25mm, 28mm, 32mm, 36mm, 40mm, 50mm, 75mm and other specifications of precision rolled threaded steel.

Product parameter:

Product Parameters | |||

Nominal Diameter / mm | Level | Nominal cross-sectional area / mm2 | Theoretical weight kg/m |

Φ15 | PSB830 | 177 | 1.4 |

Φ20 | PSB500 | 314 | 2.47 |

Φ25 | PSB500 / 830 / 930 / 1080 | 491 | 4.1 |

Φ32 | PSB830 / 930 / 1080 | 804 | 6.65 |

Φ36 | PSB830 / 930 / 1080 | 1080 | 8.41 |

Φ40 | PSB830 / 930 / 1080 | 1257 | 10.34 |

Φ50 | PSB830 / 930 / 1080 | 1963 | 16.28 |

Mechanical properties table:

Level | Yield Strength /Mpa | Tensile Strength /Mpa | Elongation after Fracture A/% | Total elongation at maximum force A/% | Stress Relaxation Properties | ||

Initial Stress | Stress relaxation rate after 1000h /% | ||||||

Not less than | |||||||

PSB785 | 785 | 980 | 7 | 3.5 | 0.8R | ≤3 | |

PSB830 | 830 | 1030 | 6 | ||||

PSB930 | 930 | 1080 | 6 | ||||

PSB1080 | 1080 | 1230 | 6 | ||||

Note: When there is no obvious yield, the specified non-proportional elongation strength is used instead. | |||||||

Implementation standards:

The implementation standards for finished rolled rebar are mainly based on GB/T20065-2016, which specifies in detail the category and definition, strength grade, size and shape and allowable deviation, technical requirements, test methods, inspection rules, packaging marks and quality certification of finished rolled rebar. The marking of steel bars shall comply with the following provisions: The end shall be painted according to the strength level, as follows: PSB785 is not painted, PSB830 is painted white, PSB930 is painted yellow, and PSB1080 is painted red.

SPECIFICATIONS

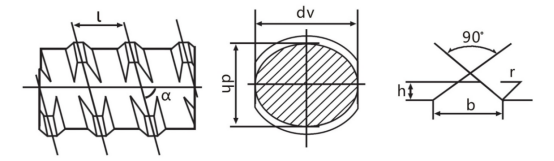

Specifications:

Diameter /mm | dh/mm | dv/mm | h/mm | b/mm | l/mm | r/mm | α | |||||

Size | Tolerance | Size | Tolerance | Size | Tolerance | Size | Tolerance | Size | Tolerance | |||

15 | 14.7 | ±0.2 | 14.4 | ±0.5 | 1.0 | ±0.2 | 4.2 | ±0.3 | 10.0 | ±0.2 | 0.5 | 78.5º |

20 | 20.0 | ±0.4 | 20.0 | +0.4-0.8 | 1.3 | ±0.3 | 4.8 | ±0.5 | 10.0 | 1.2 | 80.5º | |

25 | 25.0 | 25.0 | 1.6 | 6.0 | 12.0 | 1.5 | 81º | |||||

32 | 32.0 | ±0.5 | 32.0 | +0.5-1.2 | 2.0 | ±0.4 | 7.0 | 16.0 | 2.0 | 81.5º | ||

36 | 36.0 | 36.0 | 2.2 | ±0.4 | 8.0 | 18.0 | ±0.3 | 2.5 | 81.5º | |||

40 | 40.0 | 40.0 | 2.5 | ±0.5 | 8.0 | 20.0 | 2.5 | 81.5º | ||||

50 | 50.0 | 50.0 | 3.0 | -0.5 | 9.0 | 24.0 | 2.5 | 81.8º | ||||

Mechanical Properties:

Mechanical Properties | ||||||||||||||

Diameter / mm | Cross-sectional area / mm | Weight Kg/m | PSB830 | PSB930 | PSB1080 | |||||||||

Min Yield Stress/Load | Min Ultimate Stress/Load | Min Yield Stress/Load | Min Ultimate Stress/Load | Min Yield Stress/Load | Min Ultimate Stress/Load | |||||||||

Mpa | KN | Mpa | KN | Mpa | KN | Mpa | KN | Mpa | KN | Mpa | KN | |||

15 | 177 | 1.4 | 830 | 147 | 1030 | 182 | 930 | 165 | 1080 | 191 | 1080 | 191 | 1230 | 218 |

20 | 314 | 2.47 | 830 | 261 | 1030 | 323 | 930 | 292 | 1080 | 339 | 1080 | 339 | 1230 | 386 |

25 | 491 | 4.1 | 830 | 408 | 1030 | 506 | 930 | 457 | 1080 | 530 | 1080 | 530 | 1230 | 604 |

32 | 804 | 6.65 | 830 | 667 | 1030 | 828 | 930 | 748 | 1080 | 868 | 1080 | 868 | 1230 | 989 |

36 | 1018 | 8.41 | 830 | 845 | 1030 | 1049 | 930 | 947 | 1080 | 1099 | 1080 | 1099 | 1230 | 1252 |

40 | 1257 | 10.34 | 830 | 1043 | 1030 | 1295 | 930 | 1169 | 1080 | 1358 | 1080 | 1358 | 1230 | 1546 |

50 | 1963 | 16.28 | 830 | 1629 | 1030 | 2022 | 930 | 1826 | 1080 | 2120 | 1080 | 2120 | 1230 | 2414 |

Elongation at fracture A / % | ≥7 | ≥7 | ≥6 | |||||||||||

Total Elongation at max force Agt / % | ≥3.5 | |||||||||||||

Relaxation at 1000h | ≤4 | |||||||||||||

Modulus of elasticity / Mpa | 2 x 105 | |||||||||||||

Core advantages of the precision rolled threaded steel:

Precision rolled threaded steel can be directly matched with special nuts for anchoring, without welding or threading, and has a tensile strength of 835MPa~1230MPa, which is more than 30% higher than ordinary rebar (HRB500 grade about 630MPa), and is suitable for lifeline projects that require long-term stable load-bearing or dynamic loads.

PACKAGE

Box pcakaging or as customers' requirements.

Whether you'd like to get more info on what, need help with what you're creating anytime… anywhere.

Yuanxian High-tech Material is a company serving a worldwide customers base providing innovative and reliable product solution that recognizes the value of customer care.

Quick Links

Product Category

Subscribe Newsletter

Welcome to subscribe toour email message!